A bill deferred will still come due eventually. Whether the obligation is jury duty, a dentist

appointment or car maintenance, the piper will always insist on payment.

Keeping cars for the long term rather than regularly cycling

through newer cars is better for the personal bottom line, at least in terms of

large outlays of cash that succeed in purchasing only depreciation. However, the downside of keeping cars for the

long haul is that eventually, no matter how well-loved the car may be, parts

will wear out merely as a function of age and use. No amount of buffing and polishing will keep,

let’s say, an alternator with 130,000 miles on it from wearing out. Then, the well-loved but aging car will

strand its owner, perhaps twice in a week, at the roadside, demanding immediate

payment for maintenance deferred.

My well-loved car has been reminding me steadily that,

although it remains fundamentally sound, its component parts do wear down and

require maintenance and replacement. I

recently ordered all of the parts needed to replace the brakes, and have been

contemplating replacement of the springs and shocks as well. Both jobs require a fair amount of skill and

a specific set of parts and tools.

Thanks to online forums, however, neither job is beyond the capabilities

of a reasonably diligent and brave shade tree mechanic. Neither project, however, instilled in me the

necessary sense of urgency needed to force me to set aside my other

responsibilities to spend time getting dirty and, possibly, making things worse

instead of making them better.

The car shut down in the middle of the street, twice in one

week – that got my attention. Driving

home from work one day, the instruments, which are electronically actuated,

started to go haywire; eventually the radio cut out, and finally the engine

itself refused to remain running. As I

coasted to a wide spot on the side of the road, it was obvious the car had no

more electrical juice. That same

evening, after receiving a flatbed tow home, I purchased and replaced the

battery. Thinking this solved the

problem, I drove to and from work the next day.

The day after that, the car exhibited the same fluttering eyelid

behavior on the way to work, and I was only just able to park the car safely on

the side street off the canyon road I drive to the office. The flatbed driver, a clever young lady,

lacked the tow hook required to drag the car onto the truck, but figured out

how to use her portable charger to allow me to simply drive the car onto the

back of the truck. After a slow but

harrowing drive through canyon roads much too small for the truck, I pushed my

car into the garage, again. The only difference

from two days earlier is that the battery was new. It was, unfortunately, just as dead.

A quick bit of research indicated to me that I didn't have a

battery problem, but rather an alternator problem. Rebuilding or replacing alternators is

time-consuming, expensive business.

However, additional research showed that replacing a small component of

the alternator could solve the entire issue.

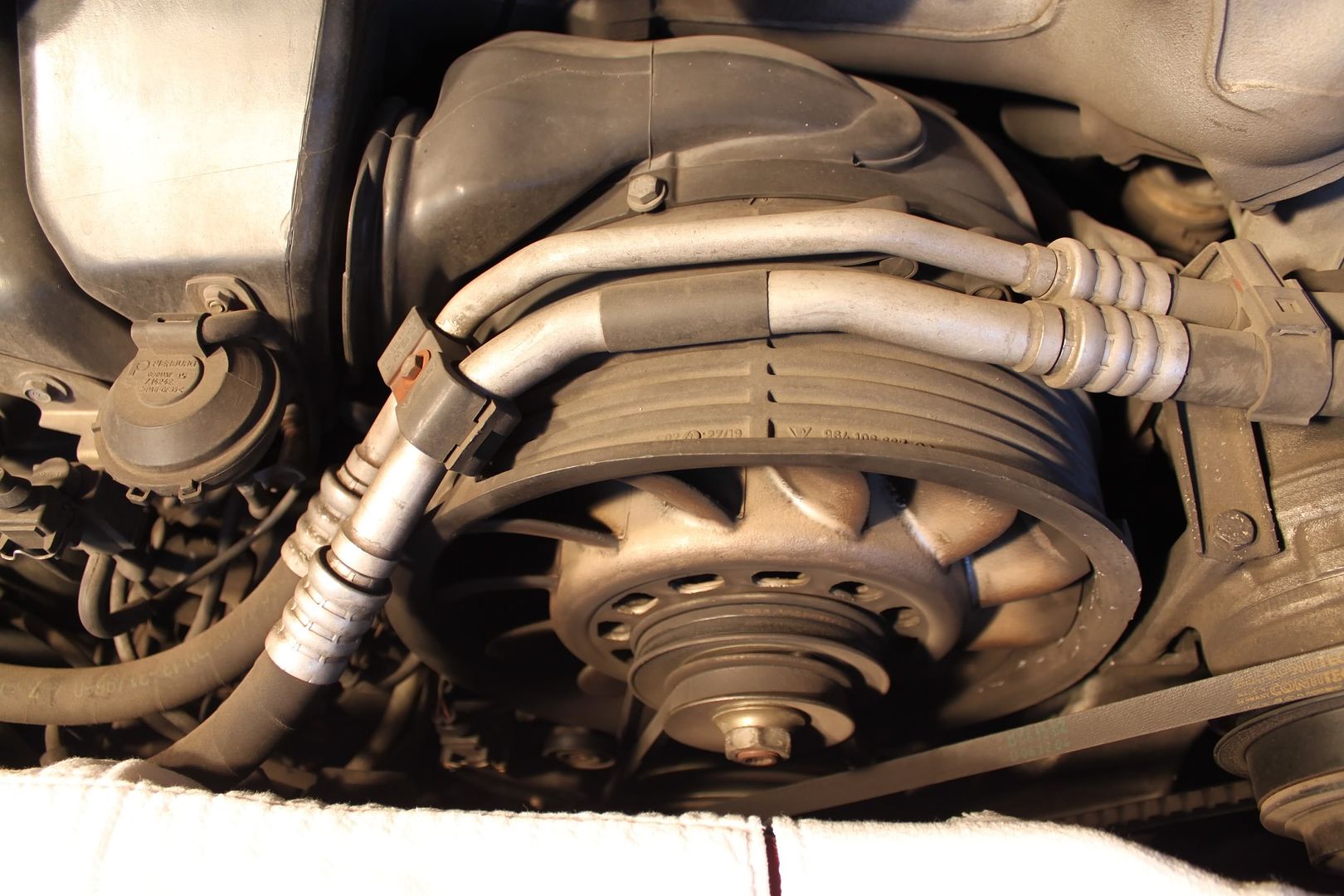

All that was required was to extract the alternator … which is connected

to the engine fan, which is connected to three different belts, one of which is

connected to the air-conditioning. The

whole project requires a specialized tool that you can't just get Sears. And all of the work must be performed in a

space the size of a pizza tray.

Given that it appeared that the problem could be completely

solved with the exchange of only a small part, I figured there was no reason to

spend ten times as much as a part on professional labor. At a busy time of year, though, and with

other cars available, it took a long time for me to get around to tackling this

project. I printed out all of the

relevant repair guides written by fellow amateur mechanics, ordered the parts I

thought I needed, went to an auto parts store to purchase additional tools I

didn't realize I needed, went back to the auto parts store to purchase another

tool to replace the first tool I bought that was the wrong size, and ordered

additional parts as spares anticipating that my typical trial-by-error methods

would leave the repair job half done unless I had replacement parts at the

ready.

I began the project last week, laying out all my tools and

parts, with extra lighting, rags and, most indispensably of all, an extendable

magnet.

|

| We're ready for you, doctor |

|

| It all started so neat and clean |

I took pictures frequently,

knowing that by the time I got around to putting the car back together, days,

if not weeks could pass, meaning I would need a strong photographic record of

what the car was supposed to look like.

|

| I sure hope it looks like this when I'm done |

After some anxious moments, a lot of grease (elbow and

otherwise) and obsessive re-checking of my references, I managed to remove the

alternator and engine fan assembly from the car.

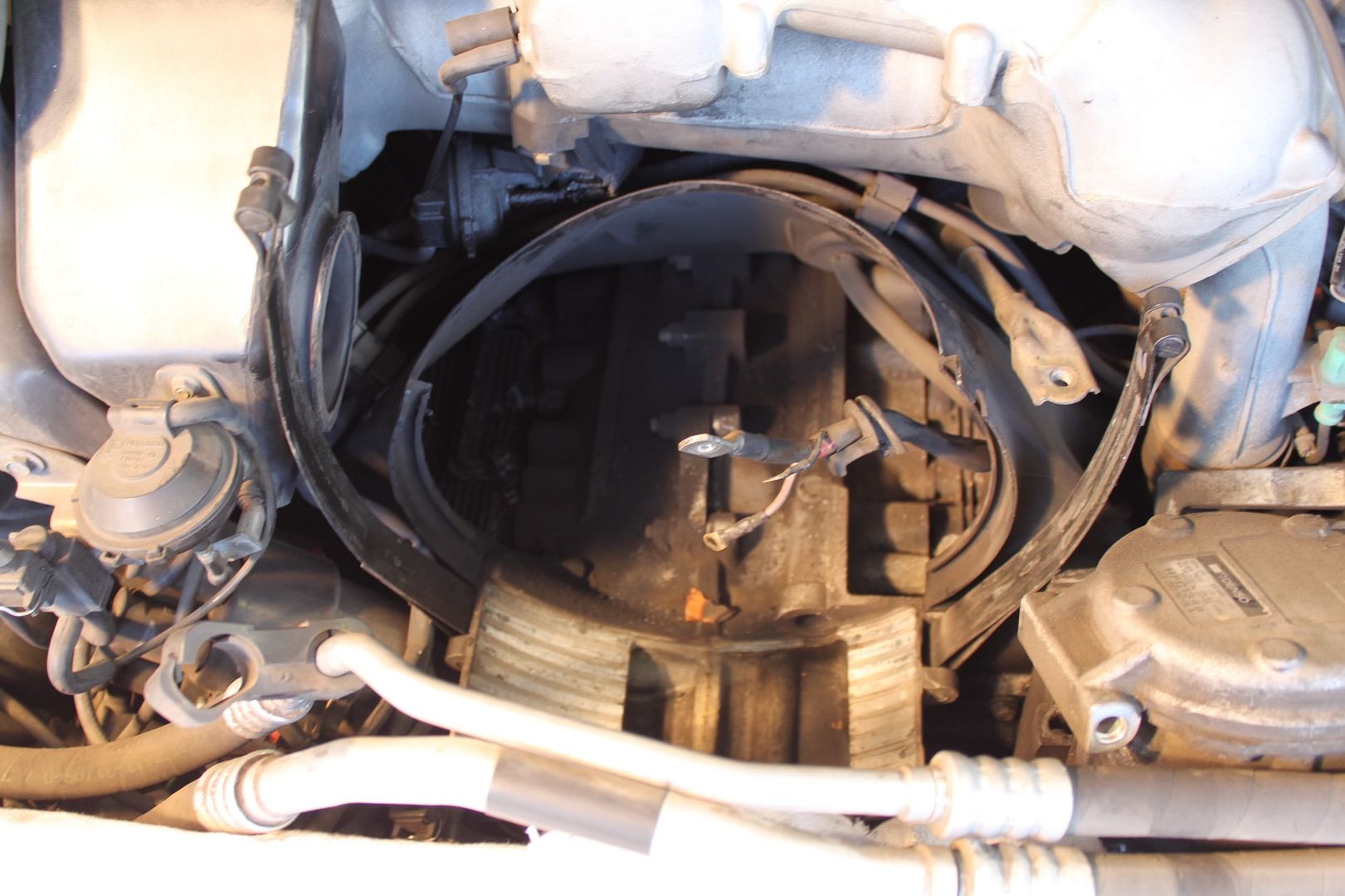

|

| We're committed now ... |

|

| ... don't break anything |

The voltage regulator, which contains the

metal "brushes" that convey electrical charge through the alternator,

was indeed thoroughly worn out.

|

| New on the left, old on the right |

The

replacement of that part took only a couple of minutes, by far the easiest

aspect of the entire job. The most difficult

portion of the project, other than becoming a contortionist to reach some of

the various nuts and bolts in the engine bay, was replacing the belts. The car uses two-part pulleys, which makes

the final adjustment of the belts a bit tricky for the neophyte mechanic. Complicating the process was the fact that

the battery was still dead, but the belt replacement procedure call for turning

the engine over to spin the crank and the pulleys in order to seat the belts

properly. One more trip to the auto

parts store for a charger, and all the pieces were literally in place to finish

the job.

Late last night, on one of the coldest evenings of the year,

I secured the last bolt, and, for the first time in two months, fired the car

up. Kelly, inside the house, could hear

me whoop and holler even over the sound of the car. It was astonishing, and extremely gratifying,

to hear the car crank right up with no bangs, clanks or warning lights. I drove the car around a while in the

immediate neighborhood to test the strength of the electrical system, and all

ended well (i.e., the car finished the drive in the garage under its own

power). After staying on the charger all

night, the battery was fully recharged this morning.

I can now tick off a few more squares on my auto mechanic’s

bingo card. In addition to repairing a

worn-out component, I also replaced the belts, which were likewise due for

regular replacement. As this saga

brought home to me, I do not often get ahead of regular maintenance items, so

replacing the belts before they suffered a catastrophic failure is a major step

forward for me.

Now to deal with the water pump on the other car… but that's

another story.

No comments:

Post a Comment